Processing Capacity

Machining & Grinding

Laser Machining

Lapping & Polishing

Customize

Machining & Grinding

Grinding is the first process used for ceramic materials. Ceramic grinding refers to the surface processing of ceramics with abrasive after forming or sintering. The method is to select large grain grinding wheel or electroplated diamond grinding wheel on the existing grinding machine for conventional grinding.

However, ceramics have the characteristics of high hardness and strong wear resistance, so different processing technologies are needed to treat different product requirements. Different processing methods can be used when processing outer circle, inner hole, plane and thread. Generally, the minimum tolerance can reach ± 0.01mm.

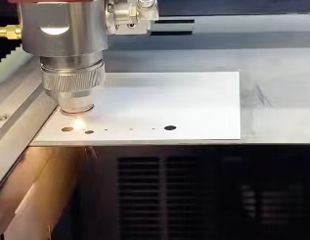

Laser Machining

Laser processing ceramic technology is to use the high-energy density laser beam to act on the surface of ceramic materials to make them melt under heat, so as to realize the processing of ceramic materials. It is mainly used to process ceramic parts or ceramic material surfaces with complex shapes and small dimensions.

Laser processing has various advantages, such as: fast processing speed; The timeliness and accuracy of processing are very high The machining accuracy is high and can reach the micron level.

But at the same time, the equipment is complex and needs experienced operators to operate. This requires higher requirements for operators. Our company is equipped with experienced operators who can process various ceramic parts according to customer requirements. For laser cutting, laser drilling, laser scribing and other processes can be completed.

Lapping & Polishing

Grinding and polishing is a kind of ultra-precision machining method. This method uses free abrasive to produce fine screening effect on the surface material to be processed, so as to achieve the processing effect. In the ultra-precision machining and finishing of ceramic materials, especially in the precision machining of ceramic balls for ceramic bearings, grinding and polishing play an irreplaceable role.

In order to further improve the surface accuracy after ceramic polishing, soft elastic or viscoelastic tools and micro-powder abrasives are used to make the surface of the workpiece reach the mirror-like finish. The mechanism of polishing is mechanical micro-removal: the micro-cutting action of the front end of the abrasive removes the concave and convex surface. Through grinding and polishing, the product can achieve the mirror effect.

Customize

Our company is equipped with special laser marking equipment, which can carve special words or logos according to customer needs. If the customer has other requirements, it can also be made according to the customer's requirements.

Production

Preparation Raw Materials

Press Molding

Kiln Sintering

Product Processing

Preparation Raw Materials

The powder is processed by physical and chemical methods to obtain the required specifications of powder; Then, according to the composition of the porcelain, various raw materials are weighed and batched, and then mixed to prepare different forms of billets according to different forming methods. Our company is equipped with special raw material processing equipment, such as ball mill, spray dryer, etc., which can control the material formula by itself.

Press Molding

Forming is to make the blank into a blank with a certain shape and specification. The slurry or powder can be made into semi-finished products with certain shapes and specifications by hot pressing, dry pressing or static pressing;

The available methods include: wet plastic molding, injection molding, molding, injection molding, hot die casting, isostatic pressure molding, plastic molding, belt molding, etc. The forming methods of industrial ceramics include dry pressing, grouting, extrusion, cold isostatic pressing, injection, casting, hot pressing and static pressing.

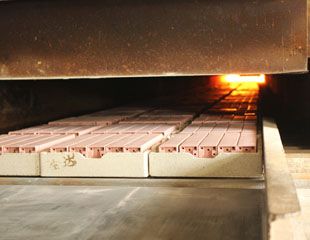

Kiln Sintering

Sintering is the process of heating the formed green body at a high temperature lower than the melting point. As the temperature rises, the powder inside the green body will bond. Through the process of material migration, it will lead to densification and high strength. During the process, the pores will be gradually eliminated, resulting in shrinkage, making the green body become a dense ceramic body with a certain strength.

Ceramic sintering methods: ordinary sintering, hot-press sintering, atmosphere sintering, hot-press sintering, etc

Product Processing

After forming and sintering, industrial ceramics can also be processed with subsequent precision as required to meet the accuracy requirements of surface roughness, shape, size, etc., such as grinding, grinding and polishing, ultrasonic processing, laser processing, and even cutting processing.)

If you have any questions or need help, feel free to contact with our team.

Phone

+86 183 5248 9056

Location

Qianluo Village, Dingshu Town, Yixing City, Jiangsu Province, China

Welcome to subscribe to our email message!

Copyright © Yixing Shengda Refractory Ceramic Co., Ltd. All Rights Reserved | Sitemap | Powered By